QUALITY AND FEATURES

MATERIAL

The quality of the steel has a crucial influence on the quality of the flatware. and is fundamental for its optimum functionality and longevity. All ZWILLING flatware is made of high-grade 18/10 stainless steel.

MATERIAL THICKNESS

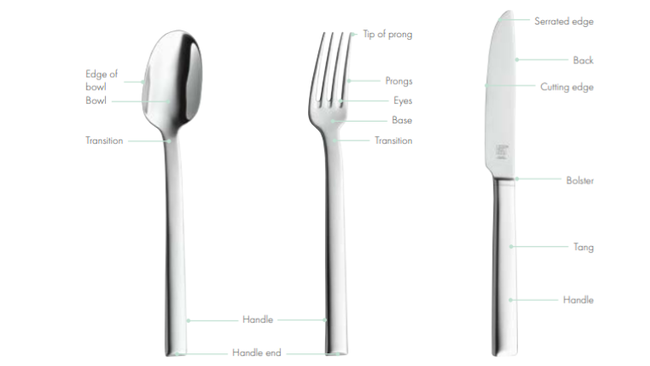

The spoons and forks of good-quality flatware should be at least 2.5 mm thick. The thicker the material, the better and more expensive is the flatware. The thickness of the material used on forks and spoons is measured above the stamp

PROCESSING

The surface of quality flatware is clean and polished or matt without any pores. The edges are soft and have no scratches or grooves. The surface between the fork's prongs is finely polished; the spoon's bowl and the fork's rim have no sharp edges. The fork prongs are pointed but have no burrs

KNIFE BLADE

The knife blade is thinly ground; it has a clean serrated edge that is sharpened on the reverse side as well.

DESIGN

The demands on flatware are very exacting. In addition to being comfortable to hold, the individual pieces need to be easy to use and look attractive. Design and ergonomics are therefore as important as their function. ZWILLING works together with well-known designers, like the renowned Milan-based designer and architect Matteo Thun, in the development of new flatware.

CARE

18/10 stainless steel flatware can be cleaned in the dishwasher.